How to choose your fertiliser

Related Articles

There is a vast choice of fertilisers available to greenkeepers but, by looking into their raw materials, it is possible to ensure optimum performance, writes Andrew McMahon.

Turf managers have a multitude of fertilisers to choose from these days, varying in analyses, release patterns, release mechanisms (controlled and slow), granule size, raw materials and manufacture just to name a few. Here are a couple of pointers to consider when trying to choose.

Many of these fertilisers are classified by name, so:

What’s in a name?

The spring / summer and autumn / winter tag names have been used for decades and have grouped fertilisers with a high nitrogen content, usually containing urea (46-0-0), together with low nitrogen fertilisers usually containing sulphate of ammonia (21-0-0). However, this historical distinction is not really relevant because we are now all aware that regular low inputs of nutrition, be it granular or liquid, is the best way to maintain plant health as it smoothes out the peaks and troughs of plant available nutrition. This means that autumn / winter products can be used year round.

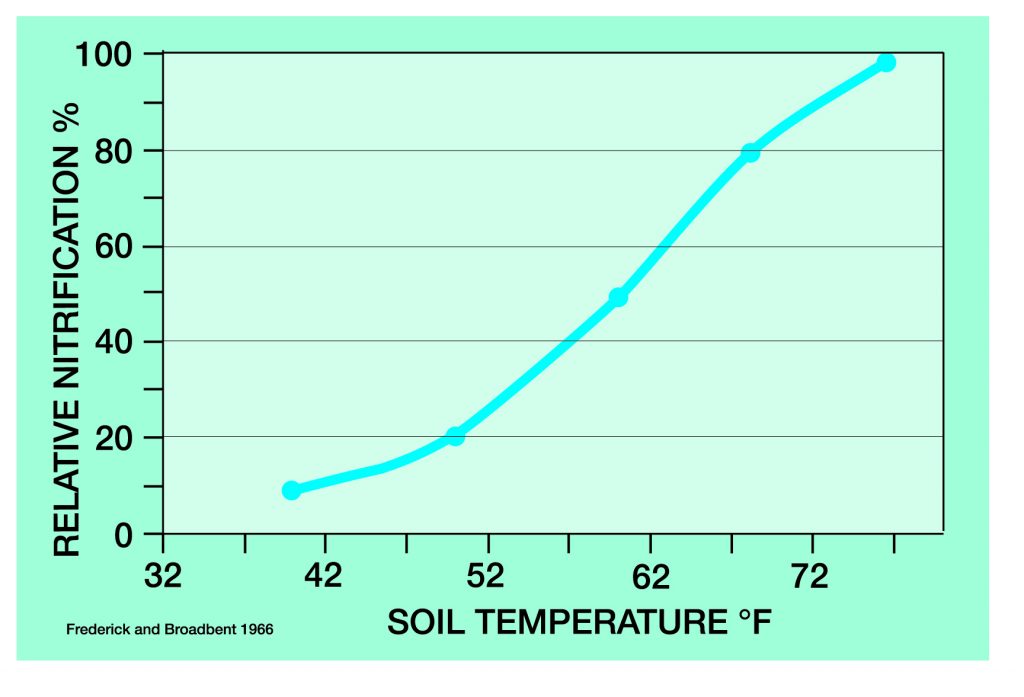

Effect of soil temperature on nitrate formation. Adapted from Frederick, L.R. and F.E. Broadbent, 1966

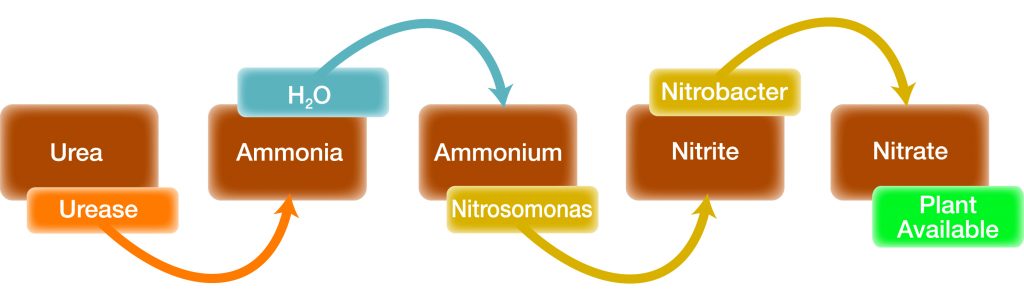

All nitrogen sources, except nitrate, must go through the process of nitrification which is the biological process in which nitrifying bacteria oxidise ammonia to nitrate to become plant available. Research has shown (see Graph A) that nitrification occurs more rapidly under warm soil temperatures.

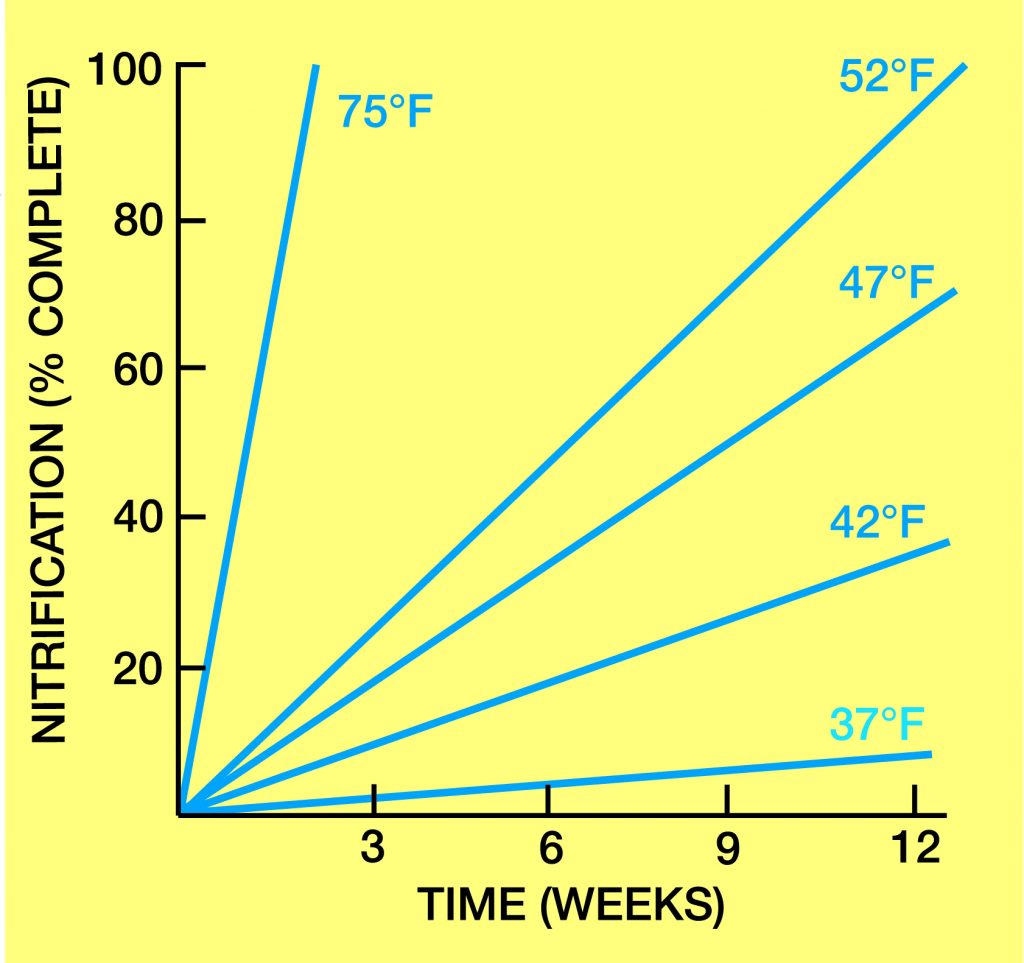

Reductions in nitrification based on temperatures. (47⁰F = 8⁰C)

Graph B above highlights how much nitrification slows in colder conditions indicating that applying sulphate of ammonia (autumn / winter fertilisers) in the summer is not a problem.

Nitrification slows because it relies on Nitrosomonas and Nitrobacter to convert the ammonia into plant available nitrate and, as with most bacteria, the colder it gets the slower they react. The optimum temperature for these to work, where nitrification is no longer limited, is approximately 75⁰F (24⁰C)

Understanding the nitrogen conversion process can help determine how a fertiliser will work, no matter what it’s called!

Urea relies on an enzyme called urease and then nitrification to become plant available. Urease prefers temperatures above 60⁰F (15⁰C) and activity increases the warmer the soil, so using a spring / summer fertilizer with urea will have its limitations in cooler conditions.

‘Cold Start’ is another fertiliser descriptive name that is bandied around these days. These fertilisers have been designed to help turf managers meet the high expectations of golfers, especially in early spring. We have seen in the graphs earlier that although sulphate of ammonia works in cooler conditions, nitrification is very limited when the temperatures drop into single figures.

We also know from the ‘Nitrogen Conversion Process’ that nitrate is readily available to the plant once it has been solubilised.

Obviously, nitrate won’t work when the ground is frozen, but once the plant is photosynthesising it can take up nitrate. This means that a Cold Start fertiliser containing nitrate will work quicker in cooler conditions than a fertiliser containing none. If you’re not sure about the contents of a fertiliser ask your supplier, they will be able to answer.

Rigby Taylor has three Cold Start fertilisers, all with nitrate, and in 2019 helped hundreds of users from the four corners of the UK, including the far north of the Cairngorms, to produce superb surfaces in early spring, with a 11-5-5+8Fe+0.8MgO analysis. This formulation has been improved with the addition of calcium providing improved turf disease tolerance.

Fertilisers are produced in two forms, compound or blend. What is the difference and why does it matter?

Cold Start fertilisers with nitrate helped golf courses all over the UK in 2019

All granular fertilisers must have a declaration panel on the bag, and this will show the source(s) of nitrogen, which could easily be three or more. There could also be multiple sources of the other nutrients used in the analysis. As an example, Rigby Taylor regularly uses at least two sources of potassium in its fertilisers.

When making a compound fertiliser, ALL nutrients and all sources are in each granule. It is fairly easy to spot a compound fertiliser, as all granules will be the same colour, usually a shade of grey / brown.

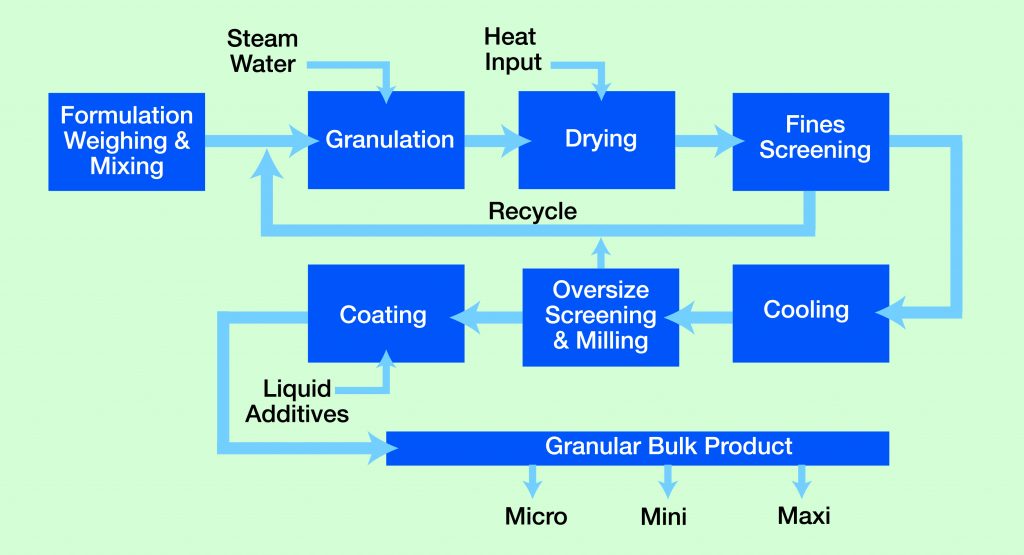

Making a compound fertiliser is a specialist operation and requires significant investment in machinery and experience. Here is a diagram showing the most modern plant in the UK where all Rigby Taylor fertilisers are produced.

Applying a compound fertiliser ensures that the whole area of the turf surface receives the same amount of nutrient, so as not to encourage any stress on the plant. Another way of minimising stress is to apply a fertiliser that has granules of a uniform size. Such uniformity reduces ballistic segregation, which is when a spreader disperses the larger, heavier granules further than smaller lighter (less dense) granules. In the worst-case scenario, when applying a multi-size blend fertiliser, the actual application rate to the turf surface can vary from 50 to 225 per cent within the swath width. This means that if the application rate is 35gm/mt², it is actually being applied somewhere between 17.5 and 80gm/mt²!

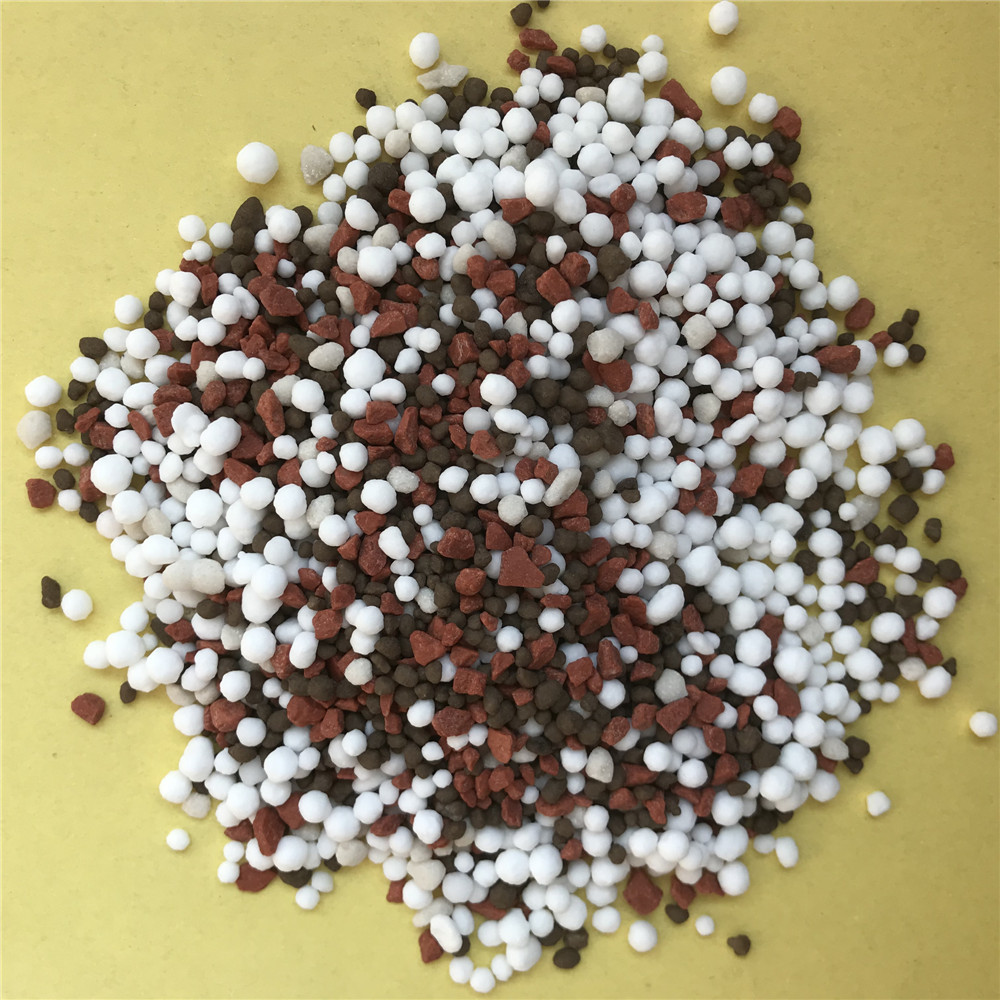

Typical multi-coloured blend fertiliser

A blend is just the physical mixing of raw materials, so one granule is just one raw material, and some analyses will have multiples ingredients.

It is obvious looking at the image that there is no way that a blended fertiliser can apply nutrients evenly and accurately. Looking closely, it can be seen that the raw materials are already separating out, this is known as sifting segregation, where smaller granules stay in the centre of the pile and larger granules accumulate at the edge. This will result in poor, inaccurate application, uneven nutrient levels, and increased risk of wear and disease stress.

The technology to produce a blended fertiliser is quite basic and requires minimal investment and little experience. All that is needed is the raw materials and a shovel. Saying that, there are some major, large scale, blending companies in the UK, the majority of which supply the agricultural market, that require a significant investment, but it will still produce a fertiliser that cannot be applied as accurately and evenly as a compound fertiliser.

Finally, as mentioned earlier, there are various fertilisers containing slow or controlled release elements. These are available in blends, but some will give better application than others. If you want to use one of these fertilisers, then it is better to go for one that in the first place is a blend of the slow release granule together with a compound granule. ConVert fertiliser is a prime example of this as it contains a coated granule (the blue / yellow / white are all the same PCSCU) and a compound granule containing Polyhalite, urea, sulphate of ammonia and other nutrients, so it is in fact a two-granule blend.

There are similar products, from different suppliers on the market, all of which have the same raw materials (maybe the slow release element is different). These products are true blends and include Polyhalite, urea, sulphate of ammonia and other nutrients, so it’s still one granule, one nutrient, with the risk of poor, uneven application, and therefore inviting stress.

It is very important with this type of fertiliser that the granule size is uniform to prevent ballistic segregation. Such fertilisers tend to be more expensive, then they should provide for excellent application uniformity.

At the end of the day, the choice of fertilisers is vast, but by looking into the raw materials rather than relying on the name, and by finding out if it’s a compound granule or a blend will ensure optimum performance when you want it, and true value for money.

Andrew McMahon is the fertiliser product manager at Rigby Taylor. For more information, visit www.rigbytaylor.com