How can the industry adapt to the loss of fungicides?

Related Articles

The industry has had to significantly adapt to the loss of fungicides in recent years but, according to Peter Corbett, STRI trials have shown we can prevent the diseases in the first place and create better surfaces in doing so.

Peter Corbett

Since 2015 the golf and sports turf sector has been severely hit by revocations (withdrawal) of fungicides. Over this period over 80 percent of Ha’s treated in the sector in 2015/16 are no longer registered for use. The active ingredients lost to the industry are:

- Prochloraz – sold as Throttle, Foremost

- Iprodione – sold as Chipco Green, Rayzor and number of parallel registered brands, Interface

- Propiconazole – sold as Banner Maxx, Nimble, Headway, Instrata.

These revoked actives have effectively removed over 20 widely used formulated product brands from the UK market.

What now?

For many greenkeepers ‘the get out of jail’ card, where highly effective fungicides could be applied when disease could be seen, has disappeared and the industry now has to focus on getting the best from the remaining products available – this can be achieved only by adopting an integrated approach, combining cultural activity together with, nutritional, biological and chemical products to manage the turf ecosystem in order to maintain the desired quality surface. Prevention, not cure is now the key word!

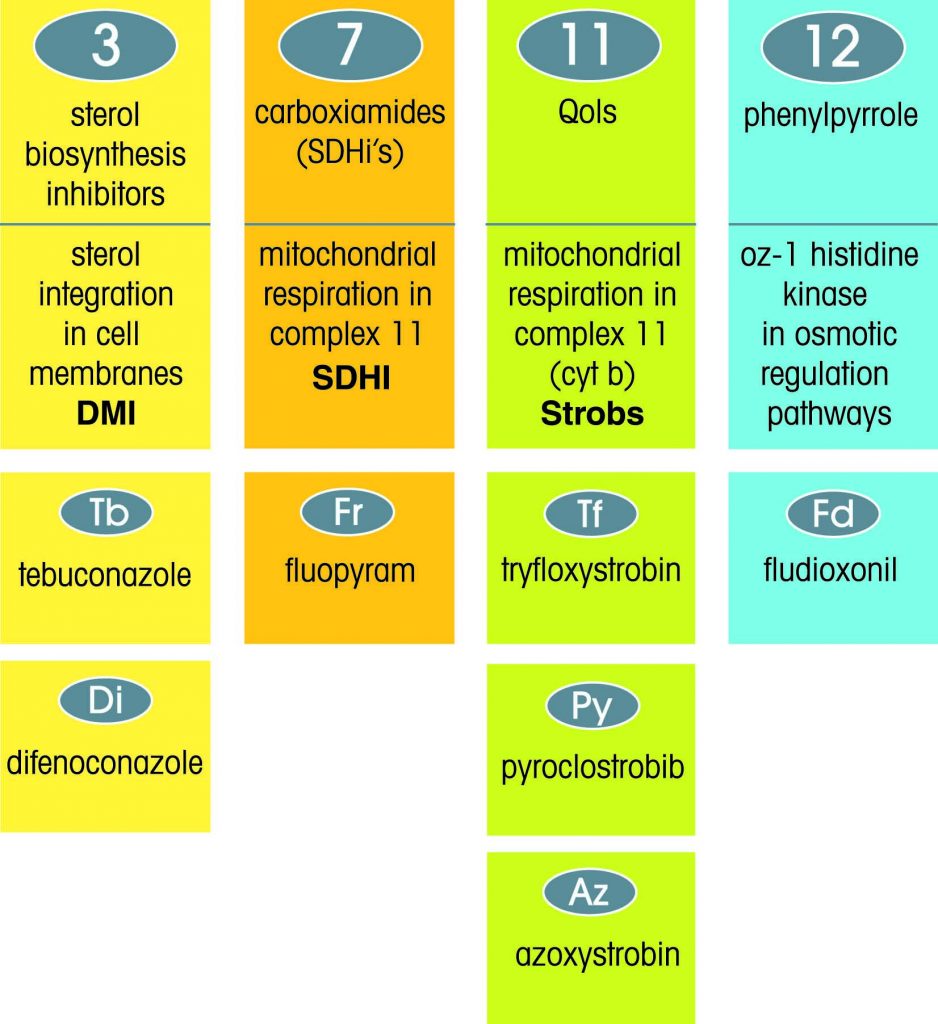

Active ingredients can be classified by mode of action using FRAC classification – the following table shows all the active ingredients registered for turf in the UK. From the table below it can be seen that the UK only has four modes of action and seven active ingredients registered. This classification is important for managing risk of disease resistance.

UK – Fungicide FRAC mode of action periodic table

Residence Risk

The active ingredients are owned by the companies Syngenta, Bayer and BASF.

To help minimise the risk of resistance manufacturers often co-formulate two active ingredients to produce a product brand, for example Fluopyram plus Trifloxystrobin is formulated with Stressgard co-formulant system to make the brand Exteris Stressgard.

Getting the best from the products we have

Firstly we need to know what is available in terms of registered products in the UK – The HSE Plant Protection Products with Authorisation for use in the UK database list all registered products.

The HSE database lists 28 product names for use on managed amenity turf. From this list, 15 of the products named are not commercially available at present.

The remaining products fit into five basic groups:

- Strobilurins – three products, two actives -Azoxystrobin (Heritage WDG), (Heritage Maxx), Pyraclostrobin (Eland)

- DMI plus Strobilurins – Tebuconazole/Trifloxystrobin – one master brand (Dedicate), six others including Fusion, Fortify, Dualitas, Tebloxy, Bestow, Oath

- Phenylpyrrole – Fludioxanil – two products (Medallion, Emblem)

- Phenylpyrrole plus DMI – Fludioxanil/Difenconazole – (Instrata Elite)

- SDHI plus Strobilurins – Fluopyram/Trifloxystrobin (Exteris Stressguard)

The role of companies like Rigby Taylor and the Origin Enterprises Group is to obtain interesting product combinations and to then understand how to get the best performance by examining:

- The formulated products

- Dose response from products

- Timing of products

- Synergy when tank-mixing.

This applies for both chemicals and nutritional products. Manufacturers will rigorously test their own products and formulations but are highly unlikely to combine actives from other companies, also they are looking to package the product in convenient sizes for shipping and distribution around the world so they do not have much flexibility to add additional co-formulants to the product.

It is in situations such as this that a company like Rigby Taylor can bring major benefits to the industry. Utilising its resources, access and communication channels with national and international research and development, chemical and nutritional companies as well as formulation specialists, it uses the facilities and knowledge at its disposal to combine all the different technologies together.

The requirements for product use on turf grasses are very specific in comparison to many used in agriculture. For example, very few arable crops are harvested two or more times a week, yet in a turf situation mowing is a critical element in turf management.

Manufacturers are constantly looking to develop unique formulations for the turf sector, but their requirements are for global products that work under a wide range of weather and disease situations. To achieve this, they often have to compromise and select the most efficacious or cost effective formulations to cover the geography they sell to. This may not be the optimum for the vagaries of the UK climate and therefore it becomes necessary to carry out or commission one’s own trials to determine which combinations work best under UK conditions.

Integrated Disease Management

The only way to achieve good control is to maximise all the cultural and nutritional disease reduction practices and use a preventative fungicide programme from late summer through to December / January, thereby building a programme of Integrated Disease Management (IDM).

To test this hypothesis, Rigby Taylor commissioned STRI to carry out a large trials programme for a full season with multiple applications using a range of products available. STRI has compared both a curative and preventative programme in autumn 2017 and 2018:

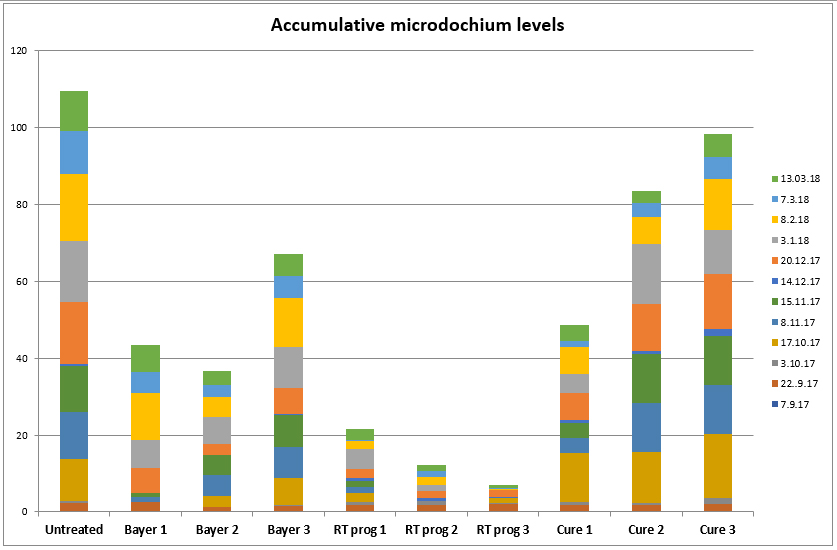

Autumn 2017. Accumulative Microdochium levels

The trial shows conclusively that prevention is better than cure. The first six programmes were applied before disease developed; the following applications were applied every 28 days. The three Rigby Taylor programmes provided statistically better disease control than the other treatments. The primary difference between treatments was the inclusion in the Rigby Taylor programmes of Trimate and Option. These products have been developed to be tank mixed with fungicides. They help the turf protect itself from disease and to aid recovery.

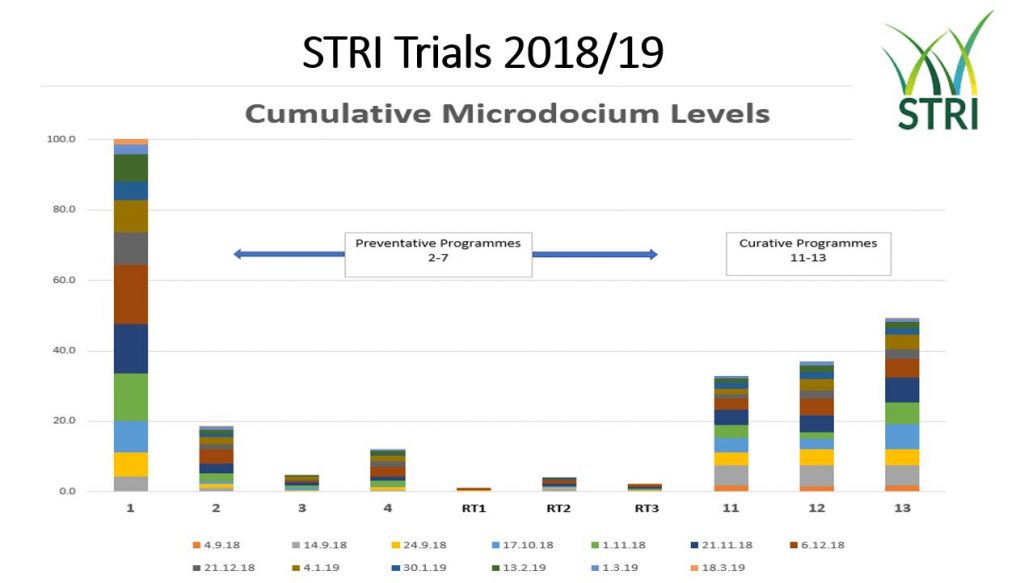

The trials series was repeated in 2018 – programmes one to three were changed but the three Rigby Taylor (RT) programmes were identical:

Autumn 2018/19 STRI Trials – Cumulative Microdochium Levels

These results clearly show prevention is better than cure and, as in the previous year, the three Rigby Taylor programmes statistically outperformed all the other treatment programmes.

Programmes RT1, RT2 and RT3

- Disease control on average was 26 percent better than other preventative programmes AND 94 percent better than curative programmes.

- Turf quality was eight percent better than other preventative programmes AND 24 percent better than curative programmes.

- Turf colour was eight percent better than other preventative programmes AND 14 percent better than curative programmes.

Rigby Taylor can now confidently offer a programme to manage late summer and autumn diseases, which has been trialled and proven across two seasons.

These trials and their widespread use conclusively show that greenkeepers should ideally be following a preventative programme, supplemented with such support products as Option, Trimate and Magnet Velocite.

To make selection and choice more understandable, Rigby Taylor’s one hectare treatment tank mix packages have been created and named for specific applications. All the tank mix components are fully tested, compatible and backed by the company. As stand-alone packages there is no measuring, chemical wasted or half empty packs left in storage.

Peter Corbett is Rigby Taylor’s chemicals product manager