Product profile: GripClad

Related Articles

Slips and trip accident always increase during autumn and winter season for a number of reasons: there is less daylight, more leaves fall onto the paths, steps and bridges become wet and slippery with the cold weather caused in ice and snow to build up on walking surfaces.

Many golf clubs have recently invested and furnished the hazard areas of their course, because fears were growing for member safety around slippery surfaces, particularly as traffic and play over the course is at its highest levels in fifteen years.

All golf courses have potential slip hazards that could be a liability that you can simply eradicate, including the hassle of legalities involved by preventing the accident in the first place.

GripClad’s cut-to-size anti-slip product gives added protection to members and players throughout the winter, and especially to those specific areas that may well be affected by rain, frost and ice. The safety of members and players has now significantly been increased with a small financial investment and minimum installation time.

Whether it be level or uneven walking surfaces, slopes, ramps, steps can all be made safe. GripClad’s unique GRP solid preformed anti-slip flat plates are supplied to in excess of over 800 golf clubs both in the UK, Ireland and Europe and is the leading brand name in this safety on the course. They have plenty of golf club testimonials if you require them.

Only high quality fibreglass composite with a diamond hard gritted surface is used in their anti-slip plates and once you install them with screws you then have a product that has an extremely low potential for slip.

The product you receive from Gripclad are constructed from a base mix of fire retardant polyester resins interspersed with layers of immensely strong interwoven glassfibre. The colour pigmentation is floated right through the full thickness of the material so that it is impossible to wear the colour off and become unsightly. The fused aluminia anti-slip grain is then forced under pressure into the base mix while it is still wet, followed by a final resin layer laid over the top of it all. This entire composite mix is then cure at optimum temperatures until fully hard.

No layering, no bonding, no weak spots, just one immensely strong composite, solid product with which you can reuse many years in the future when timbers need to be replaced.

A tidy and neat long term (20 years minimum) safety product that is retro fitted by simply screwing down onto on all walking surfaces from timber, concrete, steel, tarmac, asphalt.

The product is resistant to corrosion, frost, impact, spiked shoes, cracking, splitting, and maintenance free and also doesn’t even mark with spiked golf shoes.

The product is tested with a recorded value of 76 or above for dry conditions and 70 in wet conditions. See main advert in the October issue of GreenKeeping magazine.

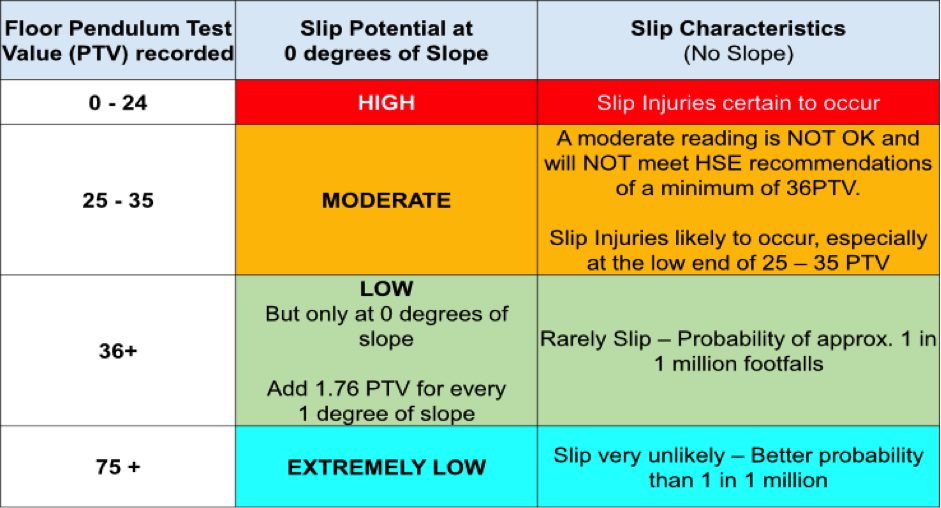

The Health & Safety Executive use The Pendulum Test Value in accordance with British & European Standard.

| Four S Pendulum Value | Potential for Slip |

| Above 65 | Extremely Low |

| 35 to 65 | Low |

| 25 to 65 | Moderate |

| 25 and Below | High |

Slip resistance properties of flooring materials are covered by various standards with Europe. BS7976 Describes the specification, operation and calibration of the Pendulum test, used for assessment of floor surface slipperiness under both dry and contaminated conditions. The results are reported as Pendulum Test Value or Slip Resistance Value and are approximately 100 times the coefficient of friction. The Pendulum Test is used routinely by the Health & Safety Laboratory on behalf of HSE.